Part A

Copper Mining Basics

Large open pit mine operations around the state (like Morenci, Ray and Bagdad) produce significant amounts of copper ore every year. Other types of geologic deposits have been mined from underground operations (like Jerome and Bisbee). The valuable ores of copper, gold, silver, etc. are usually bound with other elements to form ore minera.ls For example, the elements copper (Cu), iron (Fe), and sulfur (S) combine to make the copper ore mineral chalcopyrite (CuFeS2). Once mined, the ore minerals are extracted from less valuable waste rock, and the valuable elements are concentrated using several different processes (crushing, gravity separation, electrowinning, etc.). There are many indispensible uses for Arizona's economic minerals, although the value of the various mineral ores fluctuates in the free market.

|

Figure 13-2. There are many important aspects in copper mining extraction and processing. The Silver Bell porphyry copper mine in Arizona (left), a Cat 785G 300-ton haul truck (middle), and bundled copper plates at the Silver Bell SX-EW plant (right). |

||

Mineral resources are classified based on their economic potential. These include:

> Mineral occurrences or prospects - Deposits that are of geological interest, but may not be of economic interest

> Mineral resources - Potentially economic deposits that may or may not be feasible to extract.

> Mineral reserves - Proven or probable deposits that are both economically and technically feasible to extract. These include ore deposits.

Arizona Mining

Our civilization utilizes copper in many ways, and Arizona provides more copper than any other state in the U.S. Refer to the Wikipedia's Copper mining in Arizona web page to answer Quiz Me! questions A01 through A03.

![]()

![]()

![]()

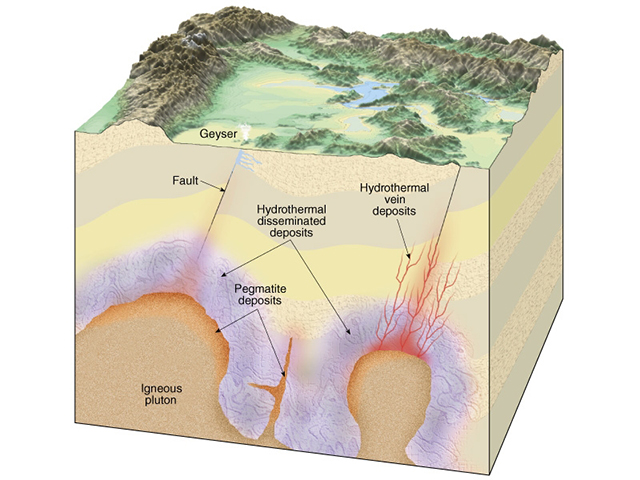

Ore Deposits

Copper deposits are formed in several ways and are commonly found in association with many other metals (gold, silver, lead, zinc, etc.). Most of the world's copper comes from porphyry copper deposits, where the copper ore body is related to intrusive igneous rocks and processes. Copper is enriched by processes during crystallization of the granite and ore bodies form when large quantities of hydrothermal fluid passes through fractured rock within and around the intrusive. Copper can precipitate out along fractures and form a vein ore deposit or spread out through a larger volume of rock and form a disseminated ore deposit. As groundwater moves through a disseminated sulfide deposit, it dissolves the dispersed metals above the water table and releases them in a zone below the water table. The relatively low-grade, disseminated ore deposits (<1% copper) are economically viable if mined in sufficient quantity by open-pit methods. Compared to disseminated ore deposits, vein deposits typically have much higher percentages of copper, but must be mined using more expensive underground methods.

|

|

|

Figure 13-3. Two major types of ore deposits: disseminated and vein (from Tarbuck and Lutgens, 2002). |

Some ore deposits form as hot, metal-rich fluids (hydrothermal fluids) migrate through rocks and fractures surrounding igneous intrusions (see Figure 13-3). As these fluids cool, various metals (Cu, Au, Ag, etc.) precipitate from solution, and combine with other elements to form ore minerals that make up some part of a larger ore body.

Disseminated Ore Deposits

> Ore minerals are spread throughout large volumes of rock.

> Economic metals in these low-grade ore deposits are present in relatively low overall concentrations (<1%).

> Extraction involves open pit mining methods.

Vein Ore Deposits

> Ore minerals are concentrated along mineral-filled fractures.

> Economic metals in these high-grade ore deposits are present in relatively high overall concentrations.

> Extraction involves underground mining methods.

Go to the Wikipedia's Porphyry copper deposit web page to answer Quiz Me! questions A04 through A06.

![]()

![]()

![]()

Mining Methods

A geologist describes an ore body by mapping the ore body and the surrounding rocks. The next step involves drilling to confirm the exact location, width, and depth of the ore body underground. Once an economically viable ore deposit has been identified, the most efficient and economical extraction method is employed. There are two main types of mining excavation processes: surface and sub-surface. Each of these has several different techniques to access the ore body. Two of the most common methods include:

Open Pit Mining - This technique is used if the ore body is large, close to the surface, and/or horizontal. In Arizona, large copper deposits are commonly associated with igneous plutons. The huge mines at Bingham Canyon, Utah and Morenci, Arizona are some of the world's largest open pit operations.

Underground Mining - A series of tunnels follow the ore body, which is usually small, deep, and/or tabular in shape. Underground mining was once more common than surface mining in Arizona. The well-known Copper Queen Mine in Bisbee is an example of an underground mine that was at its operational peak almost a century ago.

|

Figure 13-4. The two main modes of mining are open pit and underground. A typical open-pit mining operation (left). The small Hance underground mine (the adit is behind the tree) at Colorado River mile 77.8 in Grand Canyon NP. |

|

Open Pit

Let's look at the largest open-pit excavation in the world. Use the Wikipedia's Bingham Canyon mine web page to answer Quiz Me! questions A07 through A10.

![]()

![]()

![]()

![]()

Underground

Now go to the Wikipedia's Underground mining web page to answer Quiz Me! questions A11 through A13.

![]()

![]()

![]()

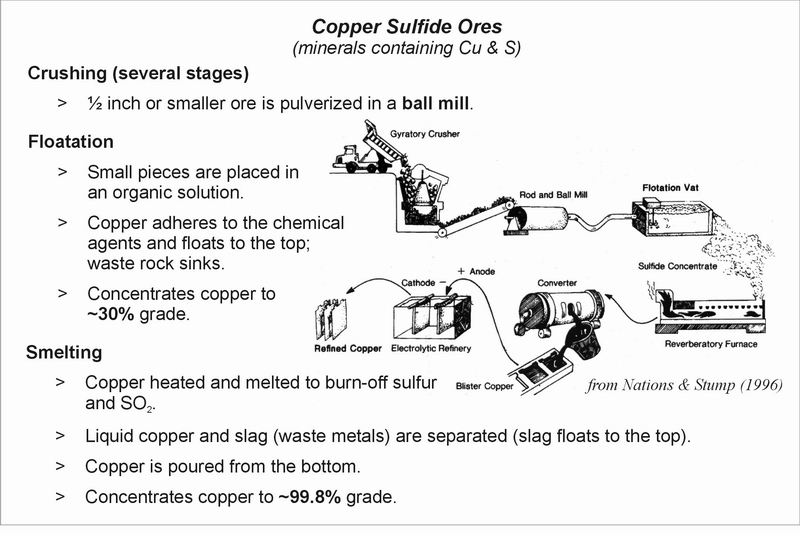

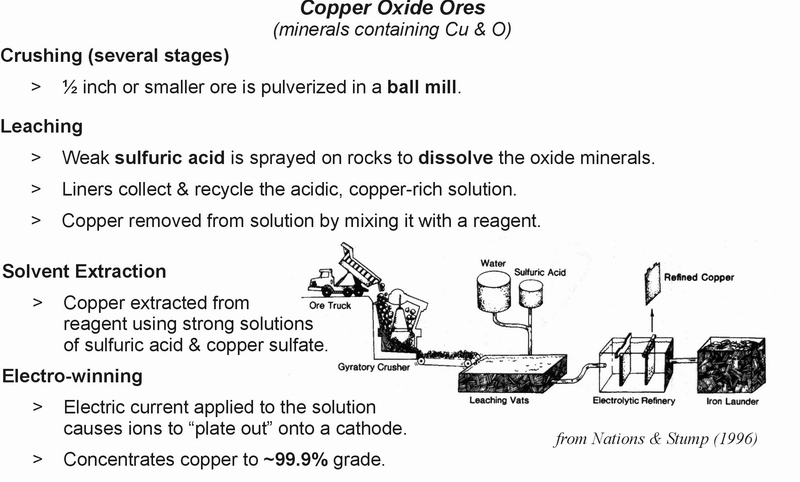

Ore Processing

Copper is extracted from copper ore in one of two ways depending on the primary type of deposit (sulfide or oxide). Both processes start out the same; blasting and digging produces rock fragments that are loaded onto conveyors huge dump trucks. The ore is unloaded into pit-crushers (up to 30 feet in diameter) that crush the rock into pieces down to less than half an inch. The rock is then pulverized using a ball mill, a giant rotating drum filled with steel balls. From here, the ore extraction method can vary, depending on the type of ore. The Wikipedia's Copper extraction web page has more information about ore processing.

Sulfide ore

A sulfide ore is passed through a flotation process where the ore minerals are mixed with an organic solution. The copper adheres to chemical agents further concentrating the copper. The mixture is then dried and sent to a smelter where it is heated at high temperatures with a flux to melt the metal, producing 99.9% pure copper.

.

|

|

|

Figure 13-5. A simiplified diagram showing the processing of copper sulfide ore. |

Oxide ore

Copper in an oxide ore is leached from its waste rock with a sulfuric acid solution. An electric current is then passed from an anode plate (+) through the acid solution containing the copper ions to a cathode plate (-). The copper then deposits onto the cathode plate. This is process is called electro-winning and results in copper that is 99.999% pure.

|

|

|

Figure 13-6. A simiplified diagram showing the processing of copper oxide ore. |

Refer to Figures 13-5 and 13-6 to answer Quiz Me! questions A14 through A19.

![]()